FEATURES

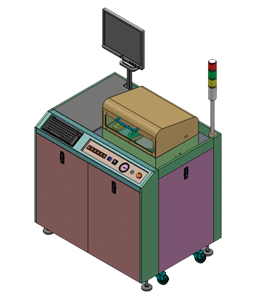

- High performance Photo-Mask cleaner Manual system.

- This very reliable and cost effective system utilizes a proven Pressure de-ionized Water or Atomizing Mist Nozzle.

- The Effective Drying technique uses High Spin Speeds and Nitrogen Assist.

- Square size 5” up to 7”.

- A genetic nerve-networking system using PC.

- The software feature enhances with specialized hardware gives high process performance.

- Traceable system and operation history.

- Operation error-free, production integrated recipe selection.

- Paperless pass-down through e-log with light indication.

- Production summary: Lot history.

- Comprehensive alarm management.

- Teach-mode calibration.

- Single/Continuous component exercise.

- Single module manual operation: Module recipe tuning.

- Unlimited flow recipes and attachable module recipes.

Software Benefit

- Distributed PC & PLC module controller.

- Interrupt controller and watchdog timer.

- PLC expandable I/O.

- 4 serial ports, 2 with RS232/422/485.

- Simplified signal wiring.

- 3 colors tower lamp.

- Modular utility monitoring.

- Easier OEM interface.

Module Controller Benefits

- Oscillating Nitrogen Blow-off Arm.

- Fan Tip Nozzle (Spray Jet).

- Oscillating D.I.W Pressure Spray Arm.

- Oscillating Brush Arm (optional).

- Radial Down-draft Exhaust/Drain.

- Chamber Liner.

- Brush Height Adjustment Knob (optional).

- Built-in Safety Interlocks and Positive Lid.

- Locking During Process Cycle.

Enhanced Hardware Benefit

SPECIFICATIONS

| System Basic | Distributed module controller |

| Size Mask | 5″-6″-7″ square |

| Mask handling | Manual |

| Mask contact & Holder | PFA, SST |

| Position accuracy | ≤ 0.1 mm |

| Maximum spin speed | 5000 rpm (5.500 rpm without mask) |

| Spin speed accuracy | ≤ 2 rpm |

| Acceleration range | 0-30000 rmp/sec |

| Acceleration accuracy | ≤5% |

| Spin direction | Clockwise (+) & Counter clockwise (-) |

| Spin Motor | Heavy-Duty-Servo 3Ø PM (ICS: 5, 62Amps, TCS: 2,88Nm, Nrtd : 5500rpm, PRTD : 1,3KW) |