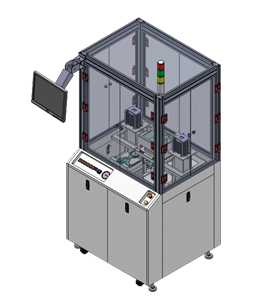

FEATURES

- HMDS Vapor-prime Oven built on production proven photo track platform.

- Suitable for IC, PSS LED, MEMs and other substrates.

- Wafer size is 4”.

- PC based central control system.

- Full featured software enhances process capability.

- Low cost for Ownership, High productivity.

- Small Foot-print.

- Traceable system and operation history.

- Operation error-free, production integrated recipe selection.

- Production summary: Lot history.

- Comprehensive alarm management.

- Teach-mode calibration.

- Single/Continuous component exercise.

- Single module manual operation: Module recipe tuning.

- Unlimited flow recipes and attachable module recipes.

Software Benefit

- Distributed PC & PLC module controller.

- Interrupt controller and watchdog timer.

- PLC expandable I/O.

- 4 serial ports, 2 with RS232/422/485.

- Simplified signal wiring.

- 3 colors tower light.

- Modular utility monitoring.

- Easier OEM interface.

Module Controller Benefits

- Digital temperature controller (Watlow).

- Special Vapor Prime Chamber design.

- Clear anodized Aluminium Material.

- Safety Interlock feature EXH, Over temp., Lid Cover.

- Designed to minimize HMDS consumption.

- Touch screen monitoring & data entry.

Enhanced Hardware Benefit

SPECIFICATIONS

| System Basic | Distributed module controller |

| Wafer size | 4″ wafer |

| Wafer handling | Random robot transfer |

| Wafer contact material | Anodized aluminum |

| Position accuracy | ≤ 0.1 mm |

| SECS/GEM | Option |